Where an objective preliminary investigation and consistency in quality are key

Netherlands based Converta has recently started successfully slitting non-woven cleaning and disinfecting materials for the hygienic WET2GO® disposable cleaning and disinfecting mops from Flash B.V. The high-tech mops are principally used for cleaning and disinfecting floors in health centres, by home help, in care homes, and also in veterinary and dental practices. The disposable WET2GO® mops absorb and dispose of bacteria and viruses, reducing the risk of cross contamination to as low as zero percent.

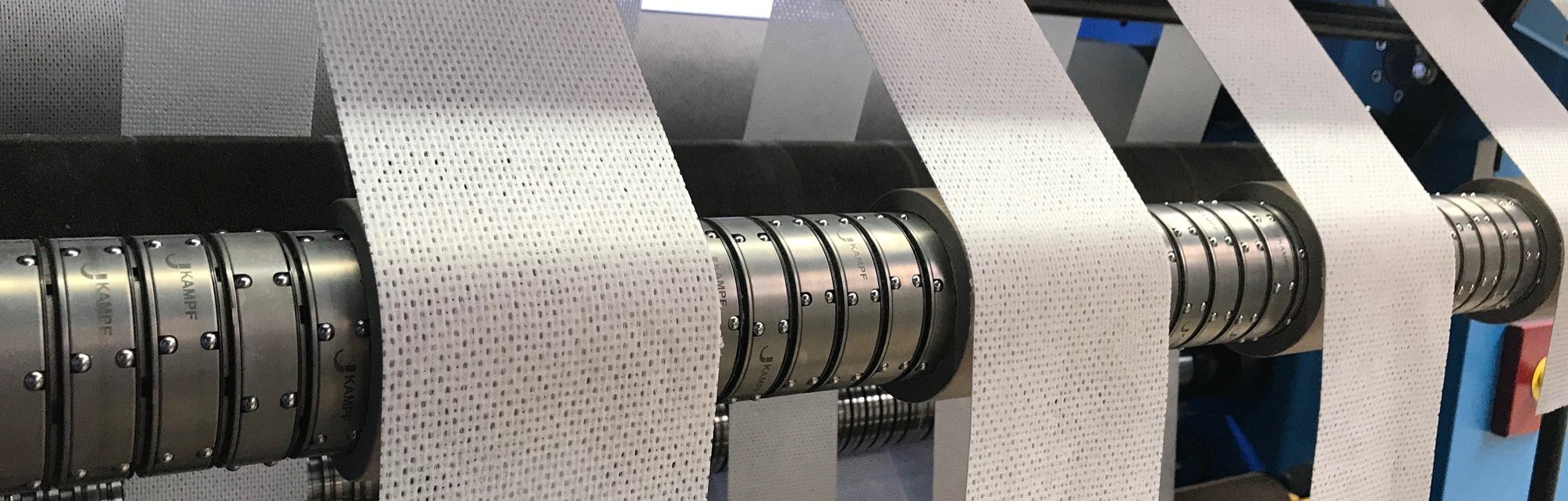

Converta performed a number of trials on the non-woven, including tests with highly advanced Kampf slitting equipment. During the assessment process a number of adjustments and additional investments were made, finally leading to an exceedingly consistent high quality semi-finished product. And well within the specific high precision slitting and hygiene tolerances required.

Flash and Converta are both extremely satisfied with the excellent end result. Naturally, all due attention has also been given to packaging to be certain that, from arrival at Converta to final delivery, all hygiene demands have been met. Converta’s stringent approach also ensured continuity in production for Flash.

One important reason Flash partnered with Converta is their consistent attention to quality. But in every aspect Converta was a success and undoubtedly the appraisal and investigation process played an integral part. Their thoroughness in carrying out this specific process in close cooperation with Flash resulted in a high quality final product.

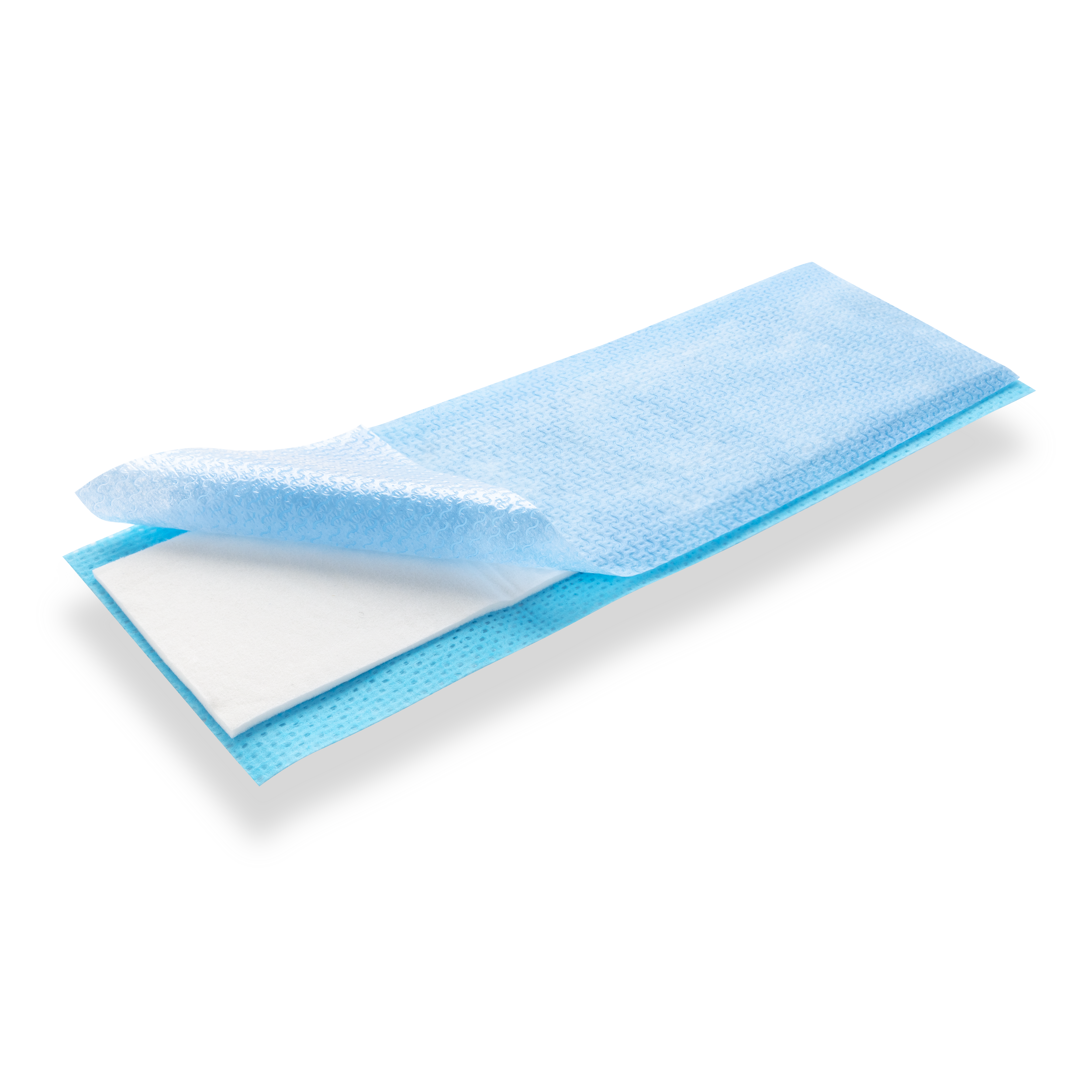

The mop itself works as follows: The mop consists of 3 layers - a cleaning layer, an absorption layer and a fixation layer with barrier film. The open structure of the cleaning layer enables easy absorption of dirt into the mop. The absorption layer ensures that the dirt is contained within the mop. The result is clean and streak-free floors. The fixation layer attaches to frames and tools. The advanced barrier film creates a hygienic barrier between dirt and the frame to which it is attached so that dirt does not come into direct contact with frames, tools and hands. Additionally, the mop absorption layer and barrier film enable a controlled disposal of the cleaning fluid, and this in turn makes for the best performance and even distribution of disinfectant or cleaning fluid onto the floor.

For more information about advanced slitting techniques and processes

For more information about WET2GO®, please see www.flash.nl