Our commitment to continuing innovation is our assurance that your end products are damage-free

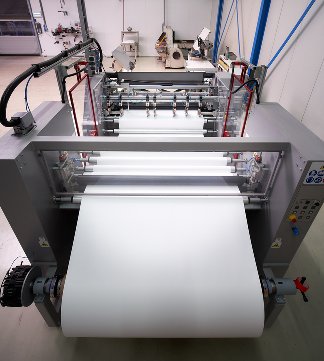

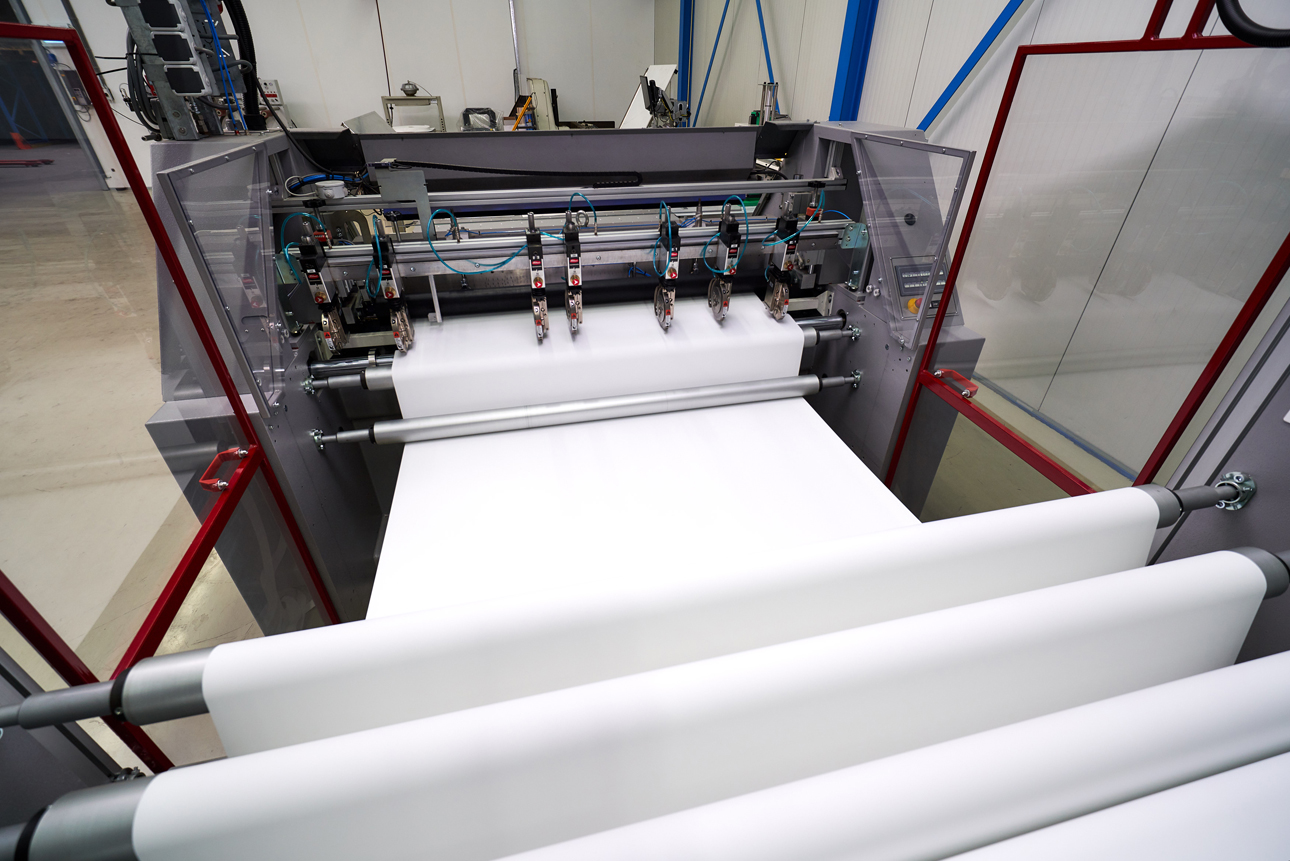

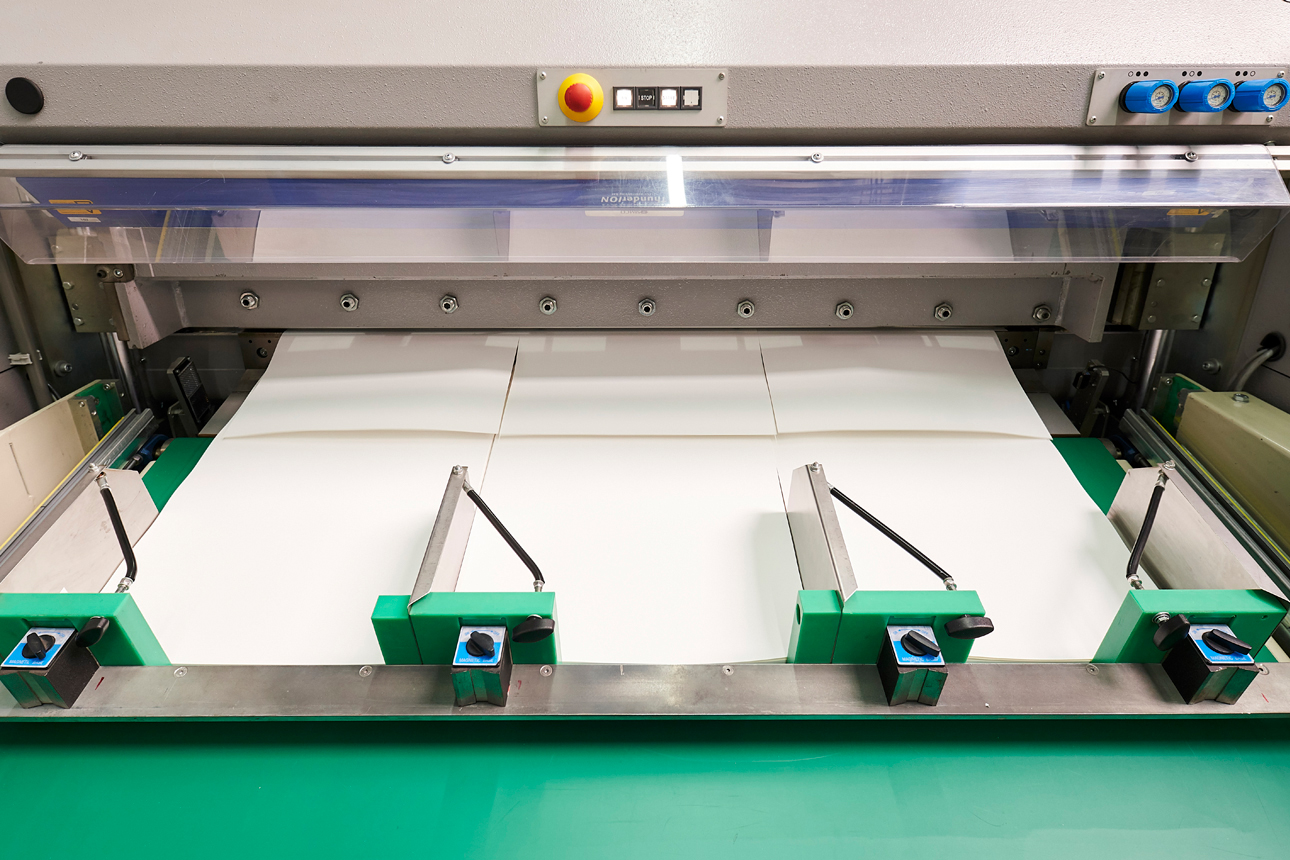

Sheet slitting, also known as sheeting, is the process of slitting printed or unprinted sheets from a larger parent roll. If desired, the parent roll is slit into strips and then cut into sheets further on in the machine. By means of a buffer and servo motors that have been perfectly attuned to each other, the material is led through the machine virtually without tension and without hitches. As a result, our modern sheeting machines can slit the sheets without causing damage. And by blowing air under the sheets on the output side of the machine, the sheets can be put on top of each other while touching them as little as possible. Extra assurance that the product will be pristine.

Consistent quality and at home in every industry

Our slitting and cutting activities include: material for larger in-mould sheets, printed materials, and materials that must be processed “scratch free” or that require a high level of accuracy. Our experienced operators carefully check the sheet slitting process, taking samples regularly and ensuring the process meets the specifications given. Like size, flatness, and how the material behaves during the process. The slitting process is adjusted accordingly. Converta is a “BRC Packaging AA” certified company. The sheets are slit in a hygienic production area, which means they are also suitable for food and medical packaging. The slit sheets meet the highest quality standards.

Slitting techniques that make the difference

We slit the material using shears (circular blades). This ensures the best possible slitting quality and produces neatly cut sides without fraying. We always take a tolerance of 1 millimetre into account.

Material-specific slitting

With our extensive knowledge and experience of materials and processing techniques, we often create special customer-specific solutions. This means that each project is given individual attention.

For example, we can cut materials that tend to be subject to stretching in two steps:

- From roll to sheet

- From sheet to sheet

After the first slitting process, the sheets will be rested for 24 hours so the stretched material can take on its original shape. The second step is to cut the sheets to size. This ensures that the material is cut accurate to the millimetre.

Material types to be slit

We can slit materials such as:

- BOPP film

- Various PET types

- Various PE types

- PVC

- Paper

- Laminates

- Or combinations thereof, with or without coatings or print.

If you are looking to slit other materials than the ones mentioned above, please do not hesitate to contact us. Converta will be happy to provide you with the best advice and create the right slitting solution for you.

Sectors and industries

The end products of the sheet slitting process find their way across industry, including:

- The Packaging Industry

- The Food Industry

- The Medical Industry

- The Printing Industry

- Industrial products

Packaging slit sheets

Sheets are packaged entirely in consultation with you, including options for tracking and tracing within our company. We use pallets with a flat closed deck, so the sheets do not get an imprint from the pallet and the stacks are perfect for further processing. Here, too, your specifications are always leading. At the same time, we will always give you the best possible advice to prevent damage or loss during transport or storage. You can find out more about packing on the “storage and transport” page.

Find out more: Converta takes care of the entire process